| Articles on

Pharmacy Design

Clean Spaces - A look at the revised and reissued USP

797 pharmacy design regulation, © William N. Bernstein,

ACHA, AIA

A revised

version of the United States Pharmacopoeia (USP) 797

“Pharmaceutical Compounding—Sterile Preparations”

regulation has been issued this year. All health

facilities that prepare compounded sterile preparations (CSPs)—pretty

much all hospital pharmacies and many off-site

pharmacies—should be aware of this new regulation, whether

or not it is adopted within the facility’s particular

state.

The 2008

version of the USP 797 regulation is the second formal

issue of the regulation by USP. The first formal issue was

in 2004. The new 2008 version contains important, new

requirements that differ substantially from the

now-superseded 2004 version.

Minimize

risk, maximize safety

The

regulation is named after a chapter published by the

United States Pharmacopoeia-National Formulary (USP-NF).

Starting with the first edition of USP 797 in 2004, and

carrying over into the current edition, USP 797 spells out

a comprehensive quality system for the design and

operation of sterile compounding areas and their support

spaces. The intent of USP 797 is twofold: to minimize the

risk of contamination of CSPs as well as to maximize the

safety of the environment for staff working in these

areas.

|

Click image to

download larger version.

|

|

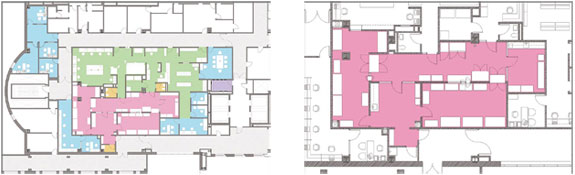

Left The overall pharmacy plan for Roswell Park

Cancer Institute.

Right Detail of

the anteroom and compounding rooms.

|

Looking now at

the details of the 2008 edition of USP 797, the general

intent of the regulation remains the same. In the words of

the first sentence of the 2008 regulation: “The objective

of this chapter is to describe conditions and practices to

prevent harm, including death, to patients” that could

result from improper compounding practices done in an

improper environment.

The standards

of the regulation are intended to apply to “all persons

who prepare CSPs and all places where CSPs are prepared

(e.g., hospitals and other health care institutions,

patient treatment clinics, pharmacies, physicians’

practice facilities and other locations and facilities in

which CSPs are prepared, stored and transported).”

The regulation

classifies five types of compounding environments:

low-risk CSPs with 12-hour beyond use dating (BUD),

low-risk, medium-risk, high-risk and immediate use. The

classification of the compounding environment influences

its required characteristics, so it is important that

clients determine their compounding risk as part of the

initial planning of any USP 797-compliant project.

Design and

construction

There

are 25 sections in the 2008 regulation, as well as four

appendices, and the regulation has far-reaching goals in

terms of the design and operation of a facility involved

with CSPs. However, the focus of this article is the

design and construction of a USP 797-compliant

environment, which is addressed in the section of the

regulation entitled: “Facility Design and Environmental

Controls.”

A good place

to start is the two key areas of the 2008 requirements

that differ substantially from the 2004 requirements. They

include the following:

ISO standard for buffer area.

In the 2008 standard, the buffer area

(the room or area where the compounding work is done) must

meet a minimum ISO 7 cleanroom standard (equivalent to a

Class 10,000 cleanroom). In the 2004 standard, the buffer

area only had to meet ISO 8 (the lower the ISO number, the

higher the standard).

ISO standard for ante area.

In the 2008 standard, the ante area

(the room or area that one passes through on the way to

the buffer area) must meet a minimum ISO 8 cleanroom

standard (equivalent to a Class 100,000 cleanroom). In the

2004 standard, the area did not have to meet an ISO

standard.

A central

element in a USP 797-compliant facility is the primary

engineering control (PEC). The PEC is the piece of

equipment, such as a laminar airflow workbench or

biological safety cabinet, where the actual aseptic

compounding activities are performed.

The PEC is

typically located within the buffer area, and the internal

work chamber within that equipment that must equal ISO 5.

In the low-risk level CSP with 12-hour BUD section, the

PEC is permitted to be located in a segregated area

(unclassified space). An example of this type of facility

configuration would be a satellite pharmacy.

In the

planning process, attention should be given to placing

these devices “out of the traffic flow and in a manner to

avoid disruption from the HVAC system and room

cross-drafts.” Selecting that piece of equipment—or

pieces, as larger compounding rooms may have several—is an

important early stage decision in the pharmacy planning

process.

Also central

to the design of a USP 797-compliant facility is the

physical relationship between the buffer area and ante

area. This physical relationship hinges around hazardous

versus non-hazardous compounding as well as the

classification of the nonhazardous compounding room as

low, medium or high risk (hazardous compounding rooms are

always classified as high risk).

There must be

a physical separation (i.e., wall and door) between the

buffer area and ante area in high-risk environments. No

physical separation is required in the other facility

classifications, however, there are daunting HVAC

requirements that come into play for “open” facilities (no

wall/door between buffer and ante areas), as we shall see

shortly.

Many

pharmacies compound substances, such as chemotherapy

drugs, referred to as hazardous drugs as defined in the

National Institute for Occupational Safety and Health (NIOSH)

publication on “Preventing Occupational Exposure to

Antineoplastic and Other Hazardous Drugs in Health Care

Settings.” These drugs are extremely toxic and dangerous

to staff if not transported, stored and handled properly.

Hazardous compounding should be done in a separate

hazardous buffer area. Some hospital pharmacies will have

two buffer areas—a hazardous buffer area and a

nonhazardous buffer area—often served by one common ante

area. One point worth mentioning here is that any ante

area serving a hazardous buffer area must be a minimum of

ISO 7 (because the air from the ante area is being drawn

into the hazardous buffer area).

For a

nonhazardous buffer area, where there is a separation

between the buffer area and the ante area, the buffer area

should be pressurized to be positive relative to the ante

area (i.e., the air should flow from the buffer area to

the ante area, so the cleaner buffer area environment is

not contaminated by the less clean ante area environment).

The regulation specifies that nonhazardous buffer areas

that have a physical separation should have a minimum,

differential, positive pressure of 0.02- to 0.05-inch

water column. Within the nonhazardous buffer area, the PEC

is a device that recirculates air within the room.

All hazardous

buffer areas must have a separation between the buffer

area and the ante area. The buffer area should be

pressurized to be negative relative the ante area (i.e.,

the air should flow into the buffer area from the ante

area, so the potentially more hazardous air of the buffer

area is contained and it does not contaminate the cleaner

ante area environment). The regulation specifies that for

these hazardous buffer areas, there should be a minimum,

differential, negative pressure of a minimum of 0.01-inch

water column between the buffer area and ante area. Within

the buffer area, the PEC must be 100 percent exhausted (no

recirculation of air) directly to the exterior through a

high-efficiency particulate air (HEPA)-filtered exhaust.

For pharmacies

that are low or medium risk, and do not compound hazardous

drugs, and where the facility has elected not to have a

physical barrier between buffer and ante areas, the

regulations specify that a system of “displacement airflow

shall be employed … (which) utilizes a low pressure

differential, high airflow principle … (which) requires an

air velocity of 40 feet per minute or more from the buffer

area across the line of demarcation into the ante area.”

It should be noted that this HVAC benchmark, which is

required of all “open” USP 797 facilities (i.e.,

facilities that do not have a wall/door between buffer

room and ante room), has been historically difficult to

achieve.

There are

additional HVAC factors to be considered in the facility

design. The first is air changes, where the regulations

specify that there be a minimum of 30 air changes per hour

(ACPH) in an ISO 7 space supplied by HEPA-filtered air.

That number of air changes could be split between the PEC

contributing no more than 15 ACPH and the HEPA-filter

supply air to the area at least 15 ACPH.

The minimum

requirement for ACPH for the buffer area is 30 ACPH and

should be based on compounding activities in the area.

Compounding processes that generate a significant amount

of particles may increase the ACPH requirements. Also, the

regulation proscribes an OR-type, unidirectional airflow

design, where the HEPA-filtered air is distributed from

supply grills in the ceiling and returned through return

grills mounted low in the wall.

Moving on to

the architectural regulations for the buffer area, only

items absolutely essential to compounding should be

brought in. Items like refrigerators, computers and

printers can be placed in a buffer area as long as there

is an accommodation for the particles they may generate.

Typically, the placement of low-wall returns behind these

devices will help sweep away any particles.

Any furniture

or equipment should be “nonpermeable, nonshedding,

cleanable and resistant to disinfectants.” All surfaces

(e.g., ceilings, walls, floors, fixtures, shelving,

counters and cabinets) should be “smooth, impervious, free

from cracks and crevices, and nonshedding.” Junctures of

ceilings to wall “shall be coved or caulked.” Wall

construction can be either epoxy-coated gypsum board, or

heavy gauge polymer panels locked together and sealed. No

sinks or floor drains are allowed in the buffer area.

Work surfaces

should be made of smooth, impervious materials such as

stainless steel or molded plastic. Carts should be made of

stainless steel wire, nonporous plastic or sheet metal

construction. Storage shelving, counters and cabinets

should also be “smooth, impervious, free from cracks and

crevices, nonshedding, cleanable and disinfectable.”

To learn more

This

article provides a general overview on the portions of the

new USP 797 regulation that pertain most to the planning,

design and construction of USP 797-compliant facilities.

General

questions can be addressed to USP at

http://usp.org.

Additionally, a selection of some of the most commonly

asked questions and answers provided by industry experts

also can be accessed at

http://usp797.org/Questions_and_Answers.htm.

William N. Bernstein, ACHA, AIA, is

a principal of Bernstein & Associates Architects in New

York. He can be contacted via his e-mail address at

wb@bernarch.com. |